马上注册,结交更多好友,享用更多功能,让你轻松玩转社区。

您需要 登录 才可以下载或查看,没有账号?注册

×

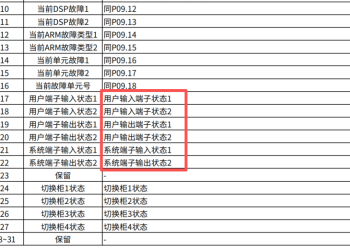

<p style="margin-left:24px;text-indent:28px"><span style="font-size:14px;font-family:'微软雅黑',sans-serif;color:windowtext">在矿井采煤面采掘时,需要可靠的支撑和控制工作面的顶板,隔离采空区,防止矸石进入回采工作面。乳化液泵与液压支架在这种需求下应运而生,乳化液泵提供液压支架所需的动力,保证乳化液的压力恒定。现有部分矿井的乳化液泵还直接使用工频启动和运行,工频启动不仅设备容易损坏,而且能耗极高。随着煤矿自动化技术的发展,变频器的应用能有效解决这些问题。英威腾Goodrive3000(简称GD3000)系列变频器采用了三电平变频技术,不仅可以实现乳化液泵电机的软启软停,并且系统配置了工频电路,保证系统稳定运行。</span></p><p style="margin-left:24px;text-indent:28px"><span style="font-size:14px;font-family:'微软雅黑',sans-serif;color:windowtext">客户痛点:</span></p><p style="margin-left:24px;text-indent:28px"><span style="font-size:14px;font-family:'微软雅黑',sans-serif;color:windowtext">1</span><span style="font-size:14px;font-family:'微软雅黑',sans-serif;color:windowtext">、传统工频运行,启动电流大,机械冲击大,影响设备的安全运行;</span></p><p style="margin-left:24px;text-indent:28px"><span style="font-size:14px;font-family:'微软雅黑',sans-serif;color:windowtext">2</span><span style="font-size:14px;font-family:'微软雅黑',sans-serif;color:windowtext">、始终全速运行,耗电量大,造成电力资源浪费;</span></p><p class="MsoListParagraph" style="margin-left:24px"><strong><span style=";font-family:'微软雅黑',sans-serif"><span style="font-variant-numeric: normal;font-variant-east-asian: normal;font-weight: normal;font-stretch: normal;font-size: 9px;line-height: normal;font-family: 'Times New Roman'"><br/></span></span></strong></p><p class="MsoListParagraph" style="margin-left:24px"><strong><span style=";font-family:'微软雅黑',sans-serif"><span style="font-variant-numeric: normal;font-variant-east-asian: normal;font-weight: normal;font-stretch: normal;font-size: 9px;line-height: normal;font-family: 'Times New Roman'"> </span></span></strong><strong><span style=";font-family:'微软雅黑',sans-serif">英威腾解决方案</span></strong></p><p class="MsoListParagraph" style="margin-left:48px"><strong><span style=";font-family:'微软雅黑',sans-serif">(1)<span style="font-variant-numeric: normal;font-variant-east-asian: normal;font-weight: normal;font-stretch: normal;font-size: 9px;line-height: normal;font-family: 'Times New Roman'"> </span></span></strong><strong><span style=";font-family:'微软雅黑',sans-serif">系统结构图</span></strong></p><p class="MsoListParagraph" style="margin-left:48px"><strong><span style=";font-family:'微软雅黑',sans-serif"><img src="/upload/article/20220402/1648891431770192.png" title="1648891431770192.png" alt="1.png"/></span></strong></p><p><strong><span style=";font-family:'微软雅黑',sans-serif"> </span></strong></p><p class="MsoListParagraph" style="margin-left:48px"><strong><span style=";font-family:'微软雅黑',sans-serif">(2)<span style="font-variant-numeric: normal;font-variant-east-asian: normal;font-weight: normal;font-stretch: normal;font-size: 9px;line-height: normal;font-family: 'Times New Roman'"> </span></span></strong><strong><span style=";font-family:'微软雅黑',sans-serif">方案整体描述</span></strong></p><p class="MsoListParagraph" style="margin-left:48px;text-indent:0"><img src="/upload/article/20220402/1648891448325041.png" title="1648891448325041.png" alt="2.png"/></p><p class="MsoListParagraph" style="margin-left:48px"><span style=";font-family:'微软雅黑',sans-serif">一般情况下一个采煤工作面配备两套乳化液泵站,一备一用,两套极少同时运行,一套泵站三相异步电机拖动,且处于长期连续运行状态,向支撑作业面的液压支架提供足够的液压。根据客户现场需求情况,英威腾采用GD3000一拖二带工频互为备用方案。需要变频器运行1号泵时合KM1,KM3,KM5,运行变频器,需要运行2号泵时合KM1,KM3,KM4,运行变频器,KM4/KM5互锁。需要工频运行1号泵时合KM2, KM5,运行变频器,需要工频运行2号泵时合KM2, KM4,运行变频器.工变频不能同时使用。</span></p><p class="MsoListParagraph" style="margin-left:48px"><span style=";font-family:'微软雅黑',sans-serif">采用本方案的由于1、2号泵互为备用,工变频互为备用,有效解决因设备问题造成停产减产问题。</span></p><p class="MsoListParagraph" style="margin-left:48px"><strong><span style=";font-family:'微软雅黑',sans-serif">(3)<span style="font-variant-numeric: normal;font-variant-east-asian: normal;font-weight: normal;font-stretch: normal;font-size: 9px;line-height: normal;font-family: 'Times New Roman'"> </span></span></strong><strong><span style=";font-family:'微软雅黑',sans-serif">技术特征</span></strong></p><p class="MsoListParagraph" style="margin-left:56px"><span style=";font-family:Wingdings">l<span style="font-variant-numeric: normal;font-variant-east-asian: normal;font-stretch: normal;font-size: 9px;line-height: normal;font-family: 'Times New Roman'"> </span></span><span style=";font-family:'微软雅黑',sans-serif">PID</span><span style=";font-family:'微软雅黑',sans-serif">调节,实现了恒压自动控制,节能效果显著;</span></p><p class="MsoListParagraph" style="margin-left:56px"><span style=";font-family:Wingdings">l<span style="font-variant-numeric: normal;font-variant-east-asian: normal;font-stretch: normal;font-size: 9px;line-height: normal;font-family: 'Times New Roman'"> </span></span><span style=";font-family:'微软雅黑',sans-serif">减少溢流阀的使用,降低机械耗损 ;</span></p><p class="MsoListParagraph" style="margin-left:56px"><span style=";font-family:Wingdings">l<span style="font-variant-numeric: normal;font-variant-east-asian: normal;font-stretch: normal;font-size: 9px;line-height: normal;font-family: 'Times New Roman'"> </span></span><span style=";font-family:'微软雅黑',sans-serif">良好的过载能力及环境适应能力,运行可靠性高;</span></p><p class="MsoListParagraph" style="margin-left:56px"><span style=";font-family:Wingdings">l<span style="font-variant-numeric: normal;font-variant-east-asian: normal;font-stretch: normal;font-size: 9px;line-height: normal;font-family: 'Times New Roman'"> </span></span><span style=";font-family:'微软雅黑',sans-serif">可实现两台泵站的切换,并且配置工频旁路;</span></p><p class="MsoListParagraph" style="margin-left:56px"><span style=";font-family:Wingdings">l<span style="font-variant-numeric: normal;font-variant-east-asian: normal;font-stretch: normal;font-size: 9px;line-height: normal;font-family: 'Times New Roman'"> </span></span><span style=";font-family:'微软雅黑',sans-serif">启动电流小,解决对泵站的冲击问题;</span></p><p class="MsoListParagraph" style="margin-left:56px"><span style="font-family: 微软雅黑, sans-serif; font-size: 14px;"><span style="font-family: Wingdings;">l</span><span style="font-variant-numeric: normal; font-variant-east-asian: normal; font-stretch: normal; font-size: 9px; line-height: normal; font-family: "Times New Roman";"> </span>具备过压,过流,缺相,过载,过温等问题具有保护功能;</span><br/></p><p><br/></p> |

FL3322 压力传感器读取器用于 TS633 PLC895 人气#I/O

FL3322 压力传感器读取器用于 TS633 PLC895 人气#I/O DA200-N伺服面板查看故障记录报警代码是Er21261 人气#通用伺服系统

DA200-N伺服面板查看故障记录报警代码是Er21261 人气#通用伺服系统 关于DA200-N通过总线驱动器通过参数0x40001187 人气#通用伺服系统

关于DA200-N通过总线驱动器通过参数0x40001187 人气#通用伺服系统 GD5000 profibus DP通信报文给定值和实际值14243 人气#高压变频器

GD5000 profibus DP通信报文给定值和实际值14243 人气#高压变频器